Thermal Characterization Study

Thermal Characterization Study

Tesla, INC

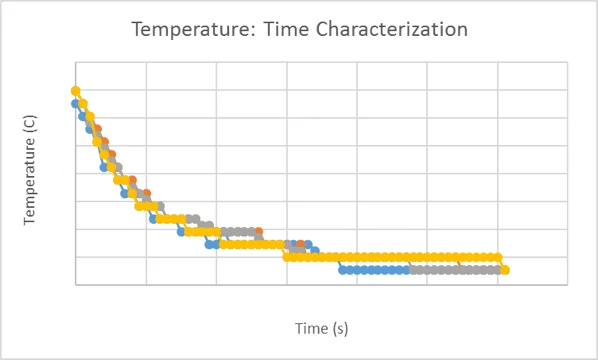

Time Characterization of Cooling Rate

*Simplified and Redacted Graph

Thermal Characterization of a single Connector

*Simplified and Redacted Graph

Objective: After determining thermal excess as the root cause of the connectivity issues: perform a thermal analysis to characterize the thermal impacts and make any design changes necessary.

Skills Used:

Root Cause Analysis

Design of Experiments

Thermal Analysis (hand calculations confirmed by experiment)

Material Selection

Process:

Determined issue was being caused due to thermal excess.

Performed thermal analysis to characterize thermal effects.

Established testing limits to prevent thermal damage for all testing connectors.

Determined material replacement.

Final Solution:

Changed material form Delrin to PEEK to increase testing capabilities.

Established testing limits (i.e. maximum amperage, and testing time) to prevent equipment damage.

Re-designed connector with heat sink to increase allowable thermal load.